Out of Sight, Out of Mind: Pathways to achieve Net-Zero Carbon Shipping

On 05.05.2020 by Christina NakhleBy Christina Nakhle

Christina Nakhle is a project manager at the ETH Zürich Sustainability in Business Lab (sus.lab) where she leads projects related to building energy systems, net zero carbon policies, and circular economy. She was a co-leader on the “Towards net zero shipping” report and is leading the work on two follow-up projects with the aim of building vessel prototypes with new technologies.

The content, graphs, and tables in this article are an outcome of sus.lab’s “Towards Net-Zero Shipping” project in 2019.

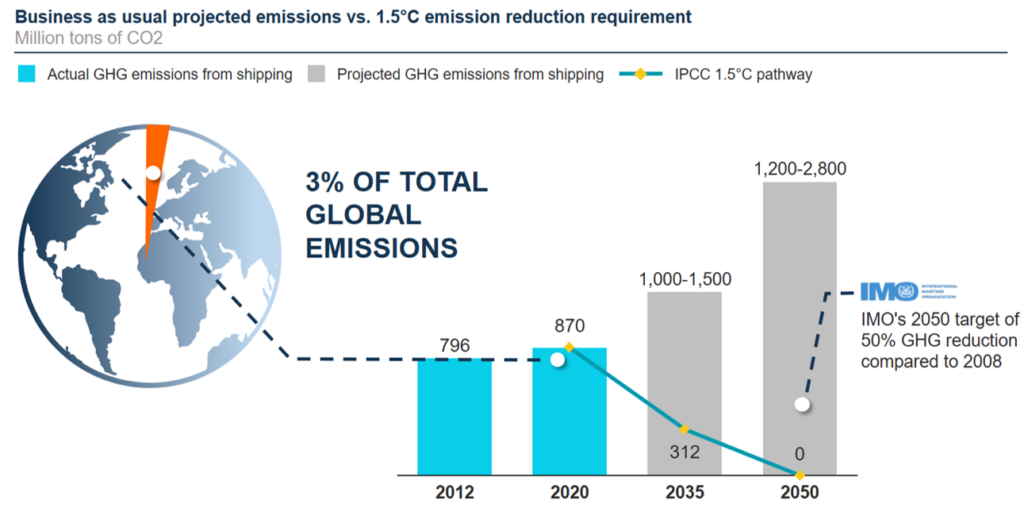

Very few individuals think of the complex value chains functioning behind the scenes, delivering the products and commodities consumed on a daily basis. In today’s global economy, maritime shipping plays an essential role in the success of international trade. As the industry is far from the consumer, the concept of “out of sight, out of mind” has so far protected it from public decarbonization pressures. Despite being the freight transport mode with the lowest CO2 emissions per tonne-kilometer, shipping accounts for 3%[1] of global greenhouse gas emissions and is expected to rise dramatically in the future.

In 2018, the International Maritime Organization (IMO) adopted the goal of reducing shipping emissions by at least 50% by 2050 compared to 2008, and complete removal by the end of this century. However, the Intergovernmental Panel on Climate Change`s (IPCC) special report on the impacts of 1.5°C warming made it clear how much humanity would gain from a more ambitious target of getting to net-zero emissions by ~2050.

Challenges of decarbonizing the shipping sector

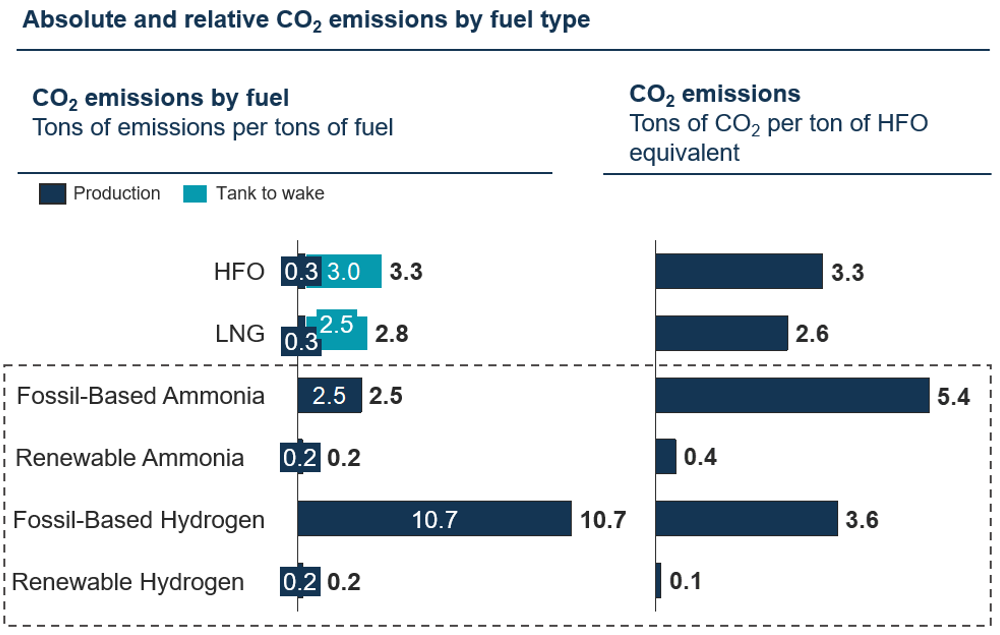

Today, heavy fuel oil (HFO), a viscous, tar-like, and dirty hydrocarbon, is the predominant fuel used by the shipping sector. Weaning off inexpensive and widely available HFO and decarbonizing the sector is challenging due to a number of factors:

(i) High cost of onboard low-carbon technologies and fuels

(ii) Uncertainty regarding the technology most likely to dominate in a low-carbon future

(iii) Long asset replacement cycles creating transitional challenges

(iv) The international and fragmented nature of the industry leading to split incentives between stakeholders, especially ship owners and operators

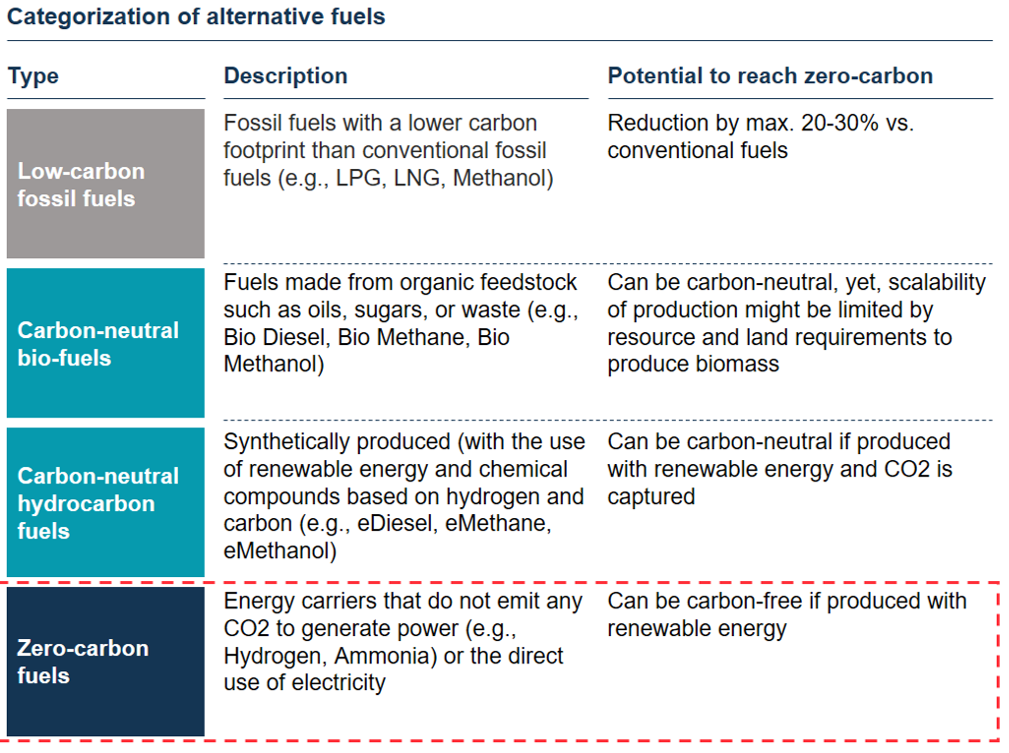

A collection of operational and technical efficiency measures can already be implemented profitably to reduce GHG emissions from shipping, including slow steaming (operating at lower speeds) and hull design optimization. Nevertheless, reaching net-zero will require a shift towards zero-carbon energy carriers such as electricity, hydrogen, and ammonia.

Alternative fuels

Pure battery-electric vessels make direct use of electricity for propulsion. In case of zero emissions, renewable electricity is stored onboard in batteries, similar to an electric vehicle. In some regions, electric ferries are already more profitable than their diesel counterparts as shown by a study in Denmark. However, the energy density of today`s batteries makes this solution viable only for short distances. The size and weight of the battery become excessive for large vessels traveling long distances.

Despite being readily available, electric shipping`s potential to cut emissions is limited. Long-distance shipping is responsible for a substantial portion of shipping emissions (87% of shipping emissions stem from international trade and 90% from large freight vessels). Thus focus needs to be set on energy carriers other than electricity, namely hydrogen and ammonia.

Fossil-based hydrogen and ammonia have been industrially produced for decades. Today about 96% of global hydrogen and ammonia production is fossil-based with a similar carbon intensity as HFO. Zero-carbon shipping will require renewable-based fuels, so there is a need to ramp up renewable hydrogen generation. According to an interviewed fuel provider, the fuel volumes demanded by the shipping industry are significant enough to trigger the required investment in renewable hydrogen production – a technological tipping point. This could spill over into other industries and launch the hydrogen economy.

There are two main paths to produce zero-carbon hydrogen:

(i) Splitting water into hydrogen and oxygen using electricity from renewables in a process called electrolysis

(ii) Extracting hydrogen from natural gas in a process called steam methane reforming in combination with carbon capture and storage to store the bi-product CO2

In an additional step, zero-carbon ammonia is produced using the Haber-Bosch process, the predominant method for fertilizer synthesis, by combining nitrogen and hydrogen.

How to move forward?

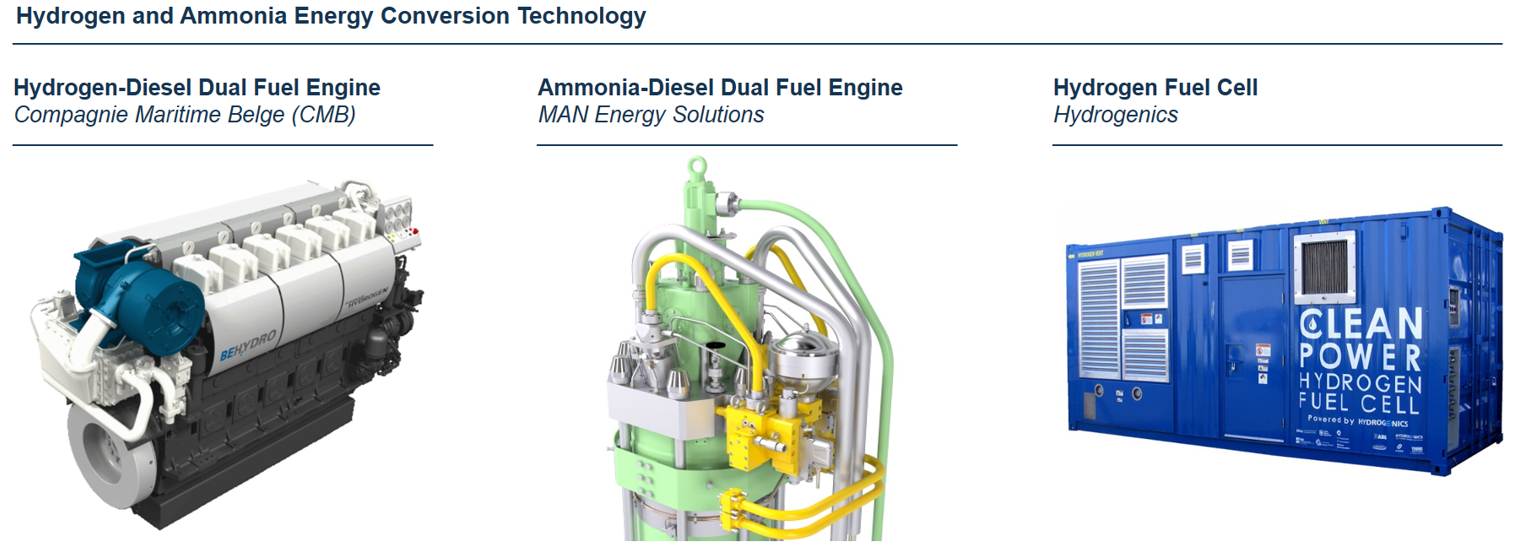

Until renewable fuels are produced at scale, the shipping industry should start testing the associated onboard technologies like hydrogen and ammonia combustion engines and fuel cells, onboard fuel storage and handling systems. These technologies are at different stages of development with some already on the market. Simultaneously, ports should start developing the appropriate infrastructure, including bunkering facilities and fuel storage. Classification societies for shipping need to begin with technical standardization. Energy providers should also be brought into the discussion, as they are a key stakeholder in the success of the zero-carbon value chain, mainly for production, but also to establish fuel distribution lanes.

Some believe that the transition will take off with increased pressure from end-customers demanding products with smaller emission footprints. However, the industry is relatively invisible to the general public and has not experienced much scrutiny over the years. Citizens regularly see traffic jams and vehicle exhaust, and planes with their white trails, yet rarely see the large clouds of black smoke leaving a ship’s exhaust. Also, consumer goods companies appear unwilling to finance the price gap between the zero-carbon and traditional solutions, according to our interviews.

Source: Pexel

The time has come to implement the “polluter pays” principle, set clear emission reduction targets and competitive incentives to enable the decarbonization of the “backbone of our economy”.

Addressing the challenges of decarbonizing the shipping sector requires multiple approaches. One player acting individually is ineffective and leads to a competitive disadvantage. Collective stakeholder action is the key to creating a fair playing field while pressuring laggards to follow and potentially solving the challenge of split incentives. The Poseidon Principles are an example of such voluntary action, providing a global framework for evaluating and disclosing the climate alignment of ship finance portfolios.

The EU and IMO need to send clear regulatory and policy signals to the industry. In the EU, policymakers should enact a CO2 levy on shipping under the ETS system for regional and international maritime emissions and use the revenues to finance investment in large-scale infrastructure, technology deployment and zero-carbon fuel uptake making costs competitive with the fossil fuel incumbent. Enforcing operational CO2 standards and setting clear emission reduction targets are also essential.

I believe the momentum for change exists and maritime players are alert and ready to move, yet legislative and policy measures are needed to push a nascent alternative for this traditional industry.

[1] Equivalent to 1 billion tonnes of CO2 and GHGs per year, on average from 2007 to 2012.

Cover photo from Cameron Venti on Unsplash

Keep up with the Energy Blog @ ETH Zurich on Twitter @eth_energy_blog.

Suggested citation: Nakhle, Christina. “Out of Sight, Out of Mind: Pathways to achieve Net-Zero Carbon Shipping ”, Energy Blog @ ETH Zurich, ETH Zurich, May 5, 2020, https://blogs.ethz.ch/energy/net-zero-carbon-shipping/

If you are part of ETH Zurich, we invite you to contribute with your findings and your opinions to make this space a dynamic and relevant outlet for energy insights and debates. Find out how you can contribute and contact the editorial team here to pitch an article idea!

Fuel costs represent as much as 50-60% of total shipping operating costs. These cost must stay low in order to avoid transportation by aircraft (18x more pollution) or rail (10x more pollution).

Substituting oil by hydrogen, biofuel or synthetic fuels of any kind is only feasible and worthwile if costs perhaps double but not if costs quadruple.

Green hydrogen (renewably generated) currently seems not to be an option, because cost would quite certainly quadruple and not only double (Prices may not come down sufficiently until the 2030s, according to IEA estimates). Blue hydrogen (Steam-Methan Reforming and Carbon Capture&Storage) is another option, but not yet proven and deployable because there are few publicly accepted Carbon Storage locations.

Biofuels could be an option in the near future if biofuel production for this purpose would be subsidized.

Hello Martin

Thank you for your comment, the points you made are very valid!

Just to explain why we did not consider biofuel as an alternative fuel option for this project: (1) it is not a zero-carbon fuel unless you can capture CO2 at the exhaust of the vessel, (2) the readily available biofuel, in our opinion, should be used in the aviation sector where the storage volume restrictions are critical.

I completely agree that the cost needs to be somewhat competitive to the HFO option. If we take the case of green H2 the fuel is 3 times more expensive if you calculate the cost per ton of MGO/HFO equivalent (to account for the energy density). A vessel operating for example on H2 with a fuel cell has a different cost structure compared to the HFO ICE alternative since for example the crew and maintenance costs can be slashed significantly. I think what needs to be kept in mind is the revenue lost due to the additional volume required by the onboard H2 tanks. However, this is countered by the compact size of fuel cells for example compared to the oversized traditional ICEs. Adjusting the H2 onboard storage to match the travel distance can also minimize the lost volume.

In conclusion, what I am trying to point out that a price comparison between green H2 or HFO propelled vessels needs to consider all cost factors and not just the fuel cost. Nevertheless, at the moment there is no business case yet for large ocean-going vessels, and that is why my final recommendation is a policy intervention (CO2 levy, fuel subsidy etc.) to drive the costs of zero-carbon fuel and technologies down.

Happy to have a further discussion!

Christina

Very interesting read! And a sector which is difficult to decarbonize.

Two comments.

First, I was wondering what happened to wind energy (e.g. in the form of large kites) supporting long distance shipping. A few years back there were some ideas and pilots(?) – is that an intermediate option some actors still consider?

Second, yet another option is to reduce long-distance transport, e.g. by making value chains less complex and more local again.

Significantly cutting future projections for shipping (cf Fig 1) should be part of a deep decarbonization strategy, I think.

Thanks Jochen!

First: Yes that is definitely still relevant and is still being tested and actually our partners on the shipping project are going to test the wind propulsion and route optimization onboard their bulk carriers and tankers. See this: https://maritime-executive.com/corporate/wind-is-the-free-fuel-for-tankers-and-bulk-carriers

Second: That is a whole other topic. I think the shipping sector itself follows the demand of the global economy. If the global system of complex value chains doesn’t change then shipping routes will not either. The IMO has no leverage to drive such a system change. Maybe we will see less complex and local manufacturing/production/harvesting etc. as a result of COVID-19 🙂

Grüezi Christina, green ammonia, produced by solar, wind etc, isn’t particularly green … please see my recent post (I’m also a new blogger but been writing about energy and food for over a decade) https://www.blog.geoffrussell.com.au/post/planet-of-the-humans-missed-lng

As an exercise, consider your Leibstadt nuclear plant … calculate the area required for solar power to generate enough electricity to replace it. It’s rather large! … now calculate the area required if you want to generate a similar amount of thermal energy from ammonia to the thermal output of Leibstadt. I think when you do these two calculations, the obvious conclusion is that large freighters should run on nuclear power. The technology is quite mature and reliable … its been used in icebreakers for decades.

@ Christina Nakhle, thanks for your answer. This followup comment concerns hydrogen, ammonia, methanol and electricity as alternative fuels for large ocean-going vessels.

Browsing the internet for future maritime fuels, the consensus seems to be:

The technical readiness for hydrogen and ammonium as fuel for large cargo ships or military support vessels is as low as 5 (Technology validated in relevant environment (industrially relevant environment in the case of key enabling technologies)).

But Methanol (from renewable feedstock) comes with a technical readiness level of 7 (System prototype demonstration in operational environment).

Large cargo ships today rely on mature technology, technology which is crucial for the world economy (even more important than airplanes).

Methanol has the potential of replacing marine gasoil in this decade because of its TRL, Hydrogen or Electricity from nuclear power could be ready in the 2030 years, but are currently not ready to replace a mature technology.

Nuclear?

One or two small molten-salt reactors on board would do,

Life of hull nuclear reactors. Submarines already have them. The us navy trains high schoolers to run them.

More domestic production. Reducing shipping volumes. Reducing production in dirtier countries.

Just in the process of writing an ebook on this very subject. Being an ex-yachtie I tend to come down on the side of wind-assisted propulsion. It is not really the complete answer of course as ships will still need engines.

Maybe all ships could be fitted with some sort of wind-assisted propulsion such as flettner rotors, wing sails, kites, dynarigs or suction wings.

Trials have shown flettner rotors capable of reducing fuel consumption by up to 20%. Surely every gram of GHG kept out of the atmosphere is an absolute plus!!

Kites used on the windy shipping routes could lower fuel consumption even more.

Wallingus have designed a giant sail-driven car carrier and the University of Tokyo is in the process of designing cape size bulk carriers. Perhaps ships of this type could carry electricity generator propellers which could be deployed when there was adequate wind-assisted propulsion, with the electricity used to drive electric motors or split hydrogen for onboard use, from seawater.

Ships of this nature will be smaller and slower but maybe this is the price that has to be paid to help save the planet.

Methanol will be the green fuel used by Maersk, the worlds biggest container shipping company according to the SPON article

Maersk-Chef Skou über grünen Sprit

»Wir müssen neue Schiffe mit fossilen Antrieben komplett verbieten«

(https://www.spiegel.de/wirtschaft/unternehmen/maersk-chef-skou-wir-muessen-neue-schiffe-mit-fossilen-antrieben-verbieten-a-44431356-6f8a-4dba-955a-dbebd679cc75 )

Reason for Methanol as fuel choice according to CEO of Maersk: READY NOW