By Katrin Sievert

Katrin Sievert is a doctoral researcher at the Climate Finance and Policy Group where she focuses her research on the costs, investment and financing needs of direct air capture, transport, and storage, as well as the assessment of appropriate financing sources.

To meet net-zero targets by mid-century, gigatons of carbon dioxide (CO2) per year must be removed through direct air capture and storage (DACS). However, current deployment is low, requiring DACS technologies to be deployed at an unprecedented pace. The blog post explores the two most advanced capture methods used in DACS, compares their scalability, and stresses the significance of investing in multiple technologies over the next decade instead of solely relying on existing approaches.

DACS has potential to make essential contributions to carbon removal from the air

According to the IPCC, it is almost certain that cumulative CO2 emissions by 2050 will exceed the “carbon budget” consistent with a climate target of well below 2°C. Consequently, in addition to comprehensive decarbonization, carbon dioxide removal (CDR) will be required on the order of gigatons (Gt) annually by 2050. Prominent approaches to CDR include nature-based solutions such as afforestation, as well as technological solutions such as direct air capture and storage of CO2 (DACS). While all CDR solutions come with risks and challenges, scientists agree that a portfolio of CDR solutions will be needed. Although DACS is currently one of the most expensive CDR options, it is considered a promising and scalable solution for permanently removing large quantities of CO2. Swiss DACS company Climeworks offers CO2 removal contracts for $600 to $1,200 per ton. In contrast, nature-based solutions like reforestation are less expensive, costing between $10 to $50 per ton, but do not provide permanent CO2 storage, resulting in the eventual release of the captured CO2 back into the air. The cost of DACS is expected to decrease alongside increased deployment, enabled by further innovation and experience mechanisms. This trajectory is potentially similar to that experienced by other low-carbon technologies, such as solar PV, which has experienced radical cost declines.

Although promising, DACS is still in a nascent stage

There are a number of promising DACS capture technologies under development. The two most advanced methodsare liquid solvent and solid sorbent DACS. Both methods use a chemical material to capture CO2 from the air and bind it, which is the decisive factor for the design of a plant. To release the CO2, the separation process requires a lot of energy, which can come from heat, electricity, or pressure. Once released, the CO2 can then be stored underground to permanently remove it from the atmosphere. The two technologies differ in how much energy is required for the separation process. Liquid solvent systems require 900°C to release a high-purity CO2 gas, while solid sorbents require around 120°C. Because of this difference, solid sorbents can use waste heat or renewable energy, while liquid solvent systems rely on natural gas. The design of the plants also differs between the two technologies. Solid sorbent plants are more modular and can be scaled up by adding more units. Liquid solvent DACS, in contrast, is a continuous process with closely interrelated components. While larger liquid solvent DACS plants are required for economic feasibility, they benefit greatly from the economies of scale.

Companies most advanced in the development of solid sorbent DACS include Global Thermostat and ETH spin-offClimeworks, while Carbon Engineering is the leading liquid solvent DACS company. Recently, there has been a wave of new companies, some of which are applying the solid sorbent or liquid solvent approach, while others are innovating to discover new DACS approaches. Heirloom, for example, developed a process that accelerates a natural reaction between CO2 in the ambient air and calcium-rich minerals to form a solid carbonate that can be processed to regenerate the minerals and create a CO2 stream. Heirloom’s process leverages longer absorption times to avoid the use of expensive materials and forced airflow through the system, potentially resulting in low overall capital costs.

To close the CDR gap, upscaling of existing and new DACS technologies are needed

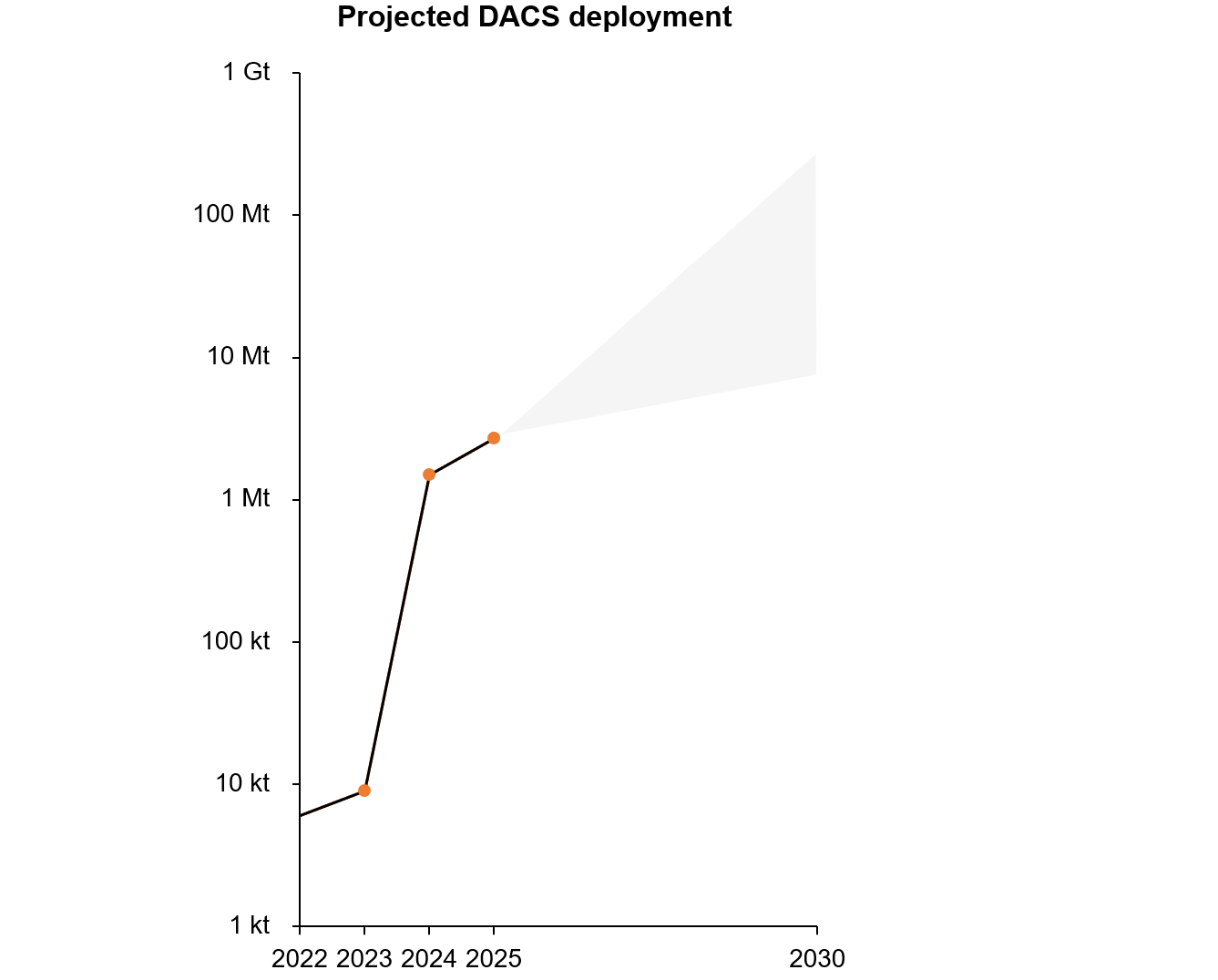

To date, 19 DACS plants of various sizes have been installed. Sizes range from 1 tCO2/year to 4,000 tCO2/year capture capacity. The total capture capacity of these plants amounts to more than 10,000 tCO2/year (10 ktCO2/year). However, to move from 10 ktCO2/year to the needed Gt-scale per year by mid-century, DACS technologies will need to scale at an unprecedented rate.

The feasibility of this unprecedented scale-up depends on several cost reduction factors. The price of energy and material inputs directly affect the cost, while further innovation and deployment would make the production process more cost efficient. Both DACS with solid sorbents and liquid solvents have potential for improvements: For example, in the solid sorbent approach, research is centered on enhancing the capacity of sorbents and scaling up their production. Meanwhile, the solvent approach involves developing novel liquid solvents with greater capacity and lower energy requirements for regeneration. The development of novel DACS approaches could also radically reduce cost. For example, beyond DACS with solid sorbents and liquid solvents, alternative DACS approaches, such as Heirloom’s process, contain features that can solve some of the problems associated with existing DACS processes.

To achieve mid-century net-zero targets, it is crucial to support the deployment of both existing and novel DACS methods, enabling DACS to scale and help close the CDR gap. To ensure the overall scale-up of the industry, it is crucial to invest in a range of DACS methods over the next decade, although the industry may eventually settle on a few predominant approaches. Relying solely on one method risks the failure of DACS to contribute to CDR, which is something the world cannot afford.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie (MSC) grant agreement No 847585

Cover photo : Own photograph of Climeworks’ DAC plant in Hinwil, Switzerland

Keep up with the Energy Blog @ ETH Zurich on Twitter @eth_energy_blog.

Suggested citation: Sievert, Katrin. “Diversifying and scaling direct air capture for a net-zero future”, Energy Blog @ ETH Zurich, ETH Zurich, February 28, 2022, https://blogs.ethz.ch/energy/diversifying-dacs

If you are part of ETH Zurich, we invite you to contribute with your findings and your opinions to make this space a dynamic and relevant outlet for energy insights and debates. Find out how you can contribute and contact the editorial team here to pitch an article idea!

Leave a Reply